Precision Fasteners

CNC Machining

CNC machining is the backbone of precision manufacturing. This process involves using advanced computer-controlled machines to perform high-precision turning, milling, grinding, and drilling on metal, plastic, and composite materials. CNC machining ensures extreme accuracy, repeatability, and efficiency, making it ideal for industries such as aerospace, automotive, medical, and electronics. The ability to produce complex geometries with tight tolerances makes CNC machining one of the most critical services in precision manufacturing.

Prototyping

Prototyping is crucial for product development, allowing companies to test and refine designs before mass production. Using technologies like CNC machining, 3D printing, and injection molding, manufacturers can create functional prototypes with high precision. Rapid prototyping services help clients validate designs, perform fit and function testing, and identify potential improvements, reducing time-to-market and production costs.

Custom Parts Manufacturing

Precision manufacturers often work with clients to produce custom parts tailored to specific applications. This service includes working from CAD drawings, material selection, and utilizing advanced manufacturing techniques to produce parts that meet strict industry requirements. Whether it’s a one-off prototype or large-scale production, manufacturers ensure high precision, durability, and consistency across all components.

Surface Finishing & Coating

Surface finishing enhances the appearance, durability, and performance of manufactured parts. Various treatments are available, including:

Polishing & Sandblasting (to improve surface texture and aesthetics)

These processes help improve the longevity and reliability of parts, especially in harsh environments.

Anodizing (for corrosion resistance and aesthetics in aluminum parts)

Powder Coating (for a durable and attractive finish)

Electroplating (adding a layer of metal like nickel or chrome for wear resistance)

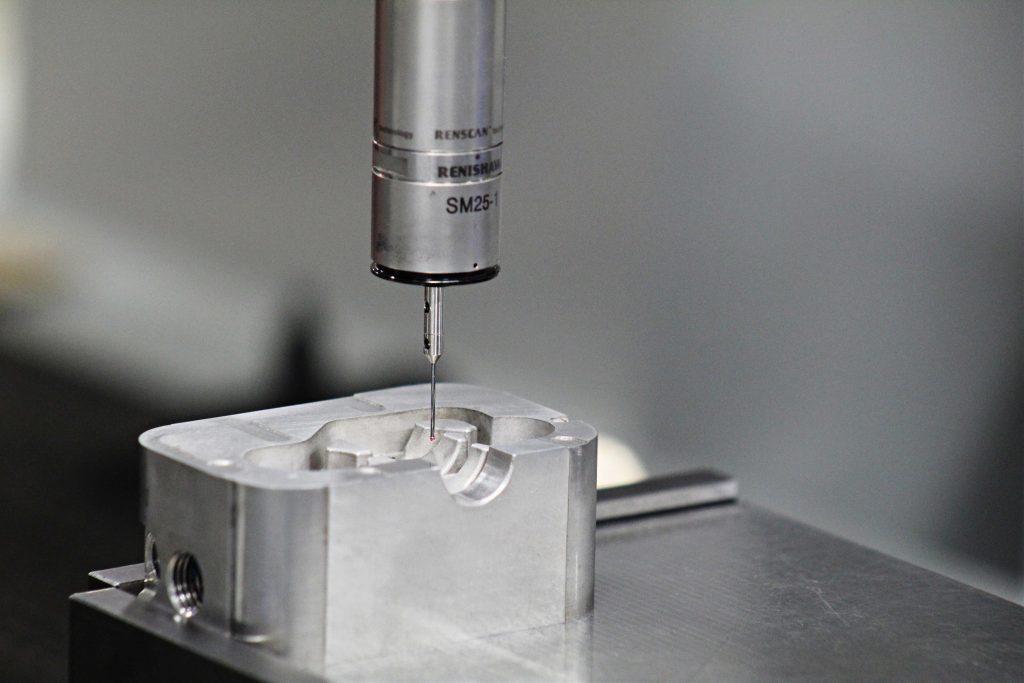

Quality Inspection & Testing

Precision manufacturers use advanced metrology tools and testing methods to ensure every part meets strict tolerances and quality standards. This includes:

Non-Destructive Testing (NDT) for identifying internal defects without damaging the part

High-quality control standards are essential for industries like medical, aerospace, and defense, where precision and reliability are critical.

Coordinate Measuring Machines (CMM) for precise dimensional analysis

Laser Scanning for 3D measurement and reverse engineering

Hardness Testing to assess material strength